-

2021

Since 1955, it seems to be a tradition in the family business that a strong man takes responsibility for the company alongside a strong woman.

Dr. Benedikt Himbert, Isabelle Mang's husband, will join the management of Arno Arnold GmbH in 2021.

Identical personal, Christian and company-specific values unite the decision-makers in the management team. Furthermore, efficiency, reliability and diligence, combined with sufficient freedom for creative leeway, are the pillars for an innovative range of services at Arno Arnold.

-

2020

Fresh in the company, Isabelle Mang already reacts to the Corona pandemic in April 2020 with a smart idea. Almost overnight, Arno Arnold develops a face visor that can be easily plugged together. A very large proportion of the visors are delivered as donations to hospitals, medical facilities and nursing homes. In times of unavailable hygiene, disinfection and protection means, they help the medical staff to protect themselves against infection with Covid 19.

-

2020

Young, female and very smart,

this is how the future of Arno Arnold GmbH continues.

Simone Weinmann-Mang and Wolf Matthias Mang are extremely pleased about the step of their daughter Isabelle to continue the traditional family business now in the 6th generation.

In January 2020 Isabelle Mang will join the management and enrich Arno Arnold from now on with her international experience, her skills and the strong will to continue the success story of Arno Arnold.

-

2019

The logistics center will be expanded and modernized. The structural connection of the new logistics center with the assembly plant ensures a smooth, rapid production cycle and speedy delivery.

A large number of new technical aids will make numerous work processes easier for employees. In this way, customers worldwide receive products from Arno Arnold in Obertshausen reliably as always, but now even faster.

-

2018

Due to fortunate circumstances, Arno Arnold was able to acquire a vacant neighboring property that directly adjoins the new industrial hall.

For future expansion plans, this provides ideal conditions to further expand at the Obertshausen site.

-

2015

Arno Arnold completes the new visitor center in Obertshausen with a new representative showroom and the extraordinary company museum.

Here, customers, guests and visitors can experience many innovative developments live and learn about the possible applications of Arnold protective covers by means of examples.

-

2014

On the occasion of the company's 150th anniversary, Arno Arnold gives itself a special present: After a blessing of a newly acquired 1,600 square meter site performed by Pastor Norbert Hofmann, the groundbreaking ceremony for the construction of a new industrial hall takes place on February 28, 2014.

With a 3 million euro investment, the managing director couple Wolf Matthias Mang and Simone Weinmann-Mang plan to increase Arno Arnold's vertical range of manufacture by building their own sheet metal production.

-

2008

Arno Arnold looks back on 10 years of successful certification according to the latest edition of the standard DIN EN ISO 9001.

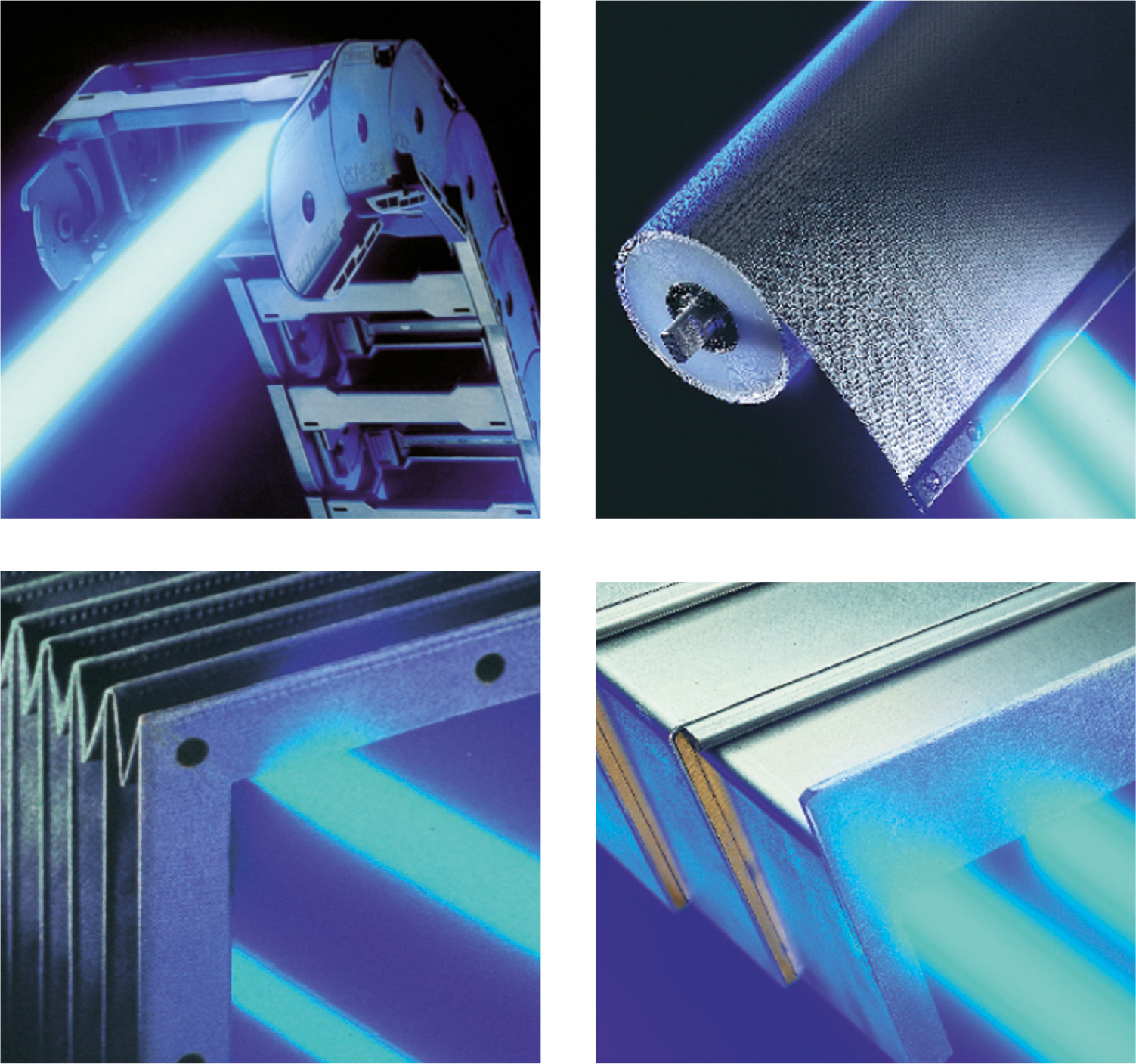

Many promising new product developments show the innovative power and strength of Arno Arnold, which is furthermore impressively proven by the registration of many patents, utility models and industrial property rights.

-

2007

In order to enable users to optimize inventories, a new high-bay warehouse was built.

An in-house technology center was also completed. In elaborate endurance tests and specific simulation procedures, the material, flexibility, robustness and travel speeds can be tested under extreme conditions. This ensures that the Arnold protective cover systems permanently meet the high requirements in daily use.

This was exactly the right step for Arno Arnold to equip itself operationally and strategically for further future challenges.

-

2006

ARNOLD grows and grows and grows...

Arno Arnold grows and grows and grows... With an increase in incoming orders of more than 20 % the company continues its upward course. With the purchase of about 1,400 sqm of production and storage space and after quickly completed renovation work, the expansion of production could be started in June 2006.

With the possibility of being able to manufacture high-quality products quickly, precisely and reliably in Germany, the European, American and increasingly also the Asian sales markets offer great opportunities. Therefore, a Chinese subsidiary was founded in Taicang this year. With innovations, customer proximity and technology leadership Arno Arnold maintains its strong position on these markets.

-

2004

Certified according to the new standard DIN EN ISO 9001:2000

In the last three years again several interesting patents and utility models were newly registered. A completely new principle for increasing the contact pressure of telescopic steel plates located in the working area is the principle of "rear clamping elements".

- This promising development and the new products

"Fix & Finish" and "Wings" show the innovative power and strength of the Arno Arnold company. -

2001

Due to the steadily increasing interest in Arnold products, the year 2001 was also marked by growth.

For this reason Arno Arnold doubled its production area at the Obertshausen location at the beginning of the year.

-

1998

Today, as then, Arnold products enjoy an international reputation. Product quality, customer proximity, service - the standards to which the company is committed have become the norm for an entire industry.

In addition, ARNO ARNOLD was certified by TÜV Hessen in 1998 with the registration number 73 100 508 according to DIN EN ISO 9001 for the development, production and distribution of protection and safety systems.

In addition, ARNO ARNOLD is a TÜV PRODUCT SERVICE certified manufacturing facility, which ensures perfect and consistent manufacturing quality. -

1989

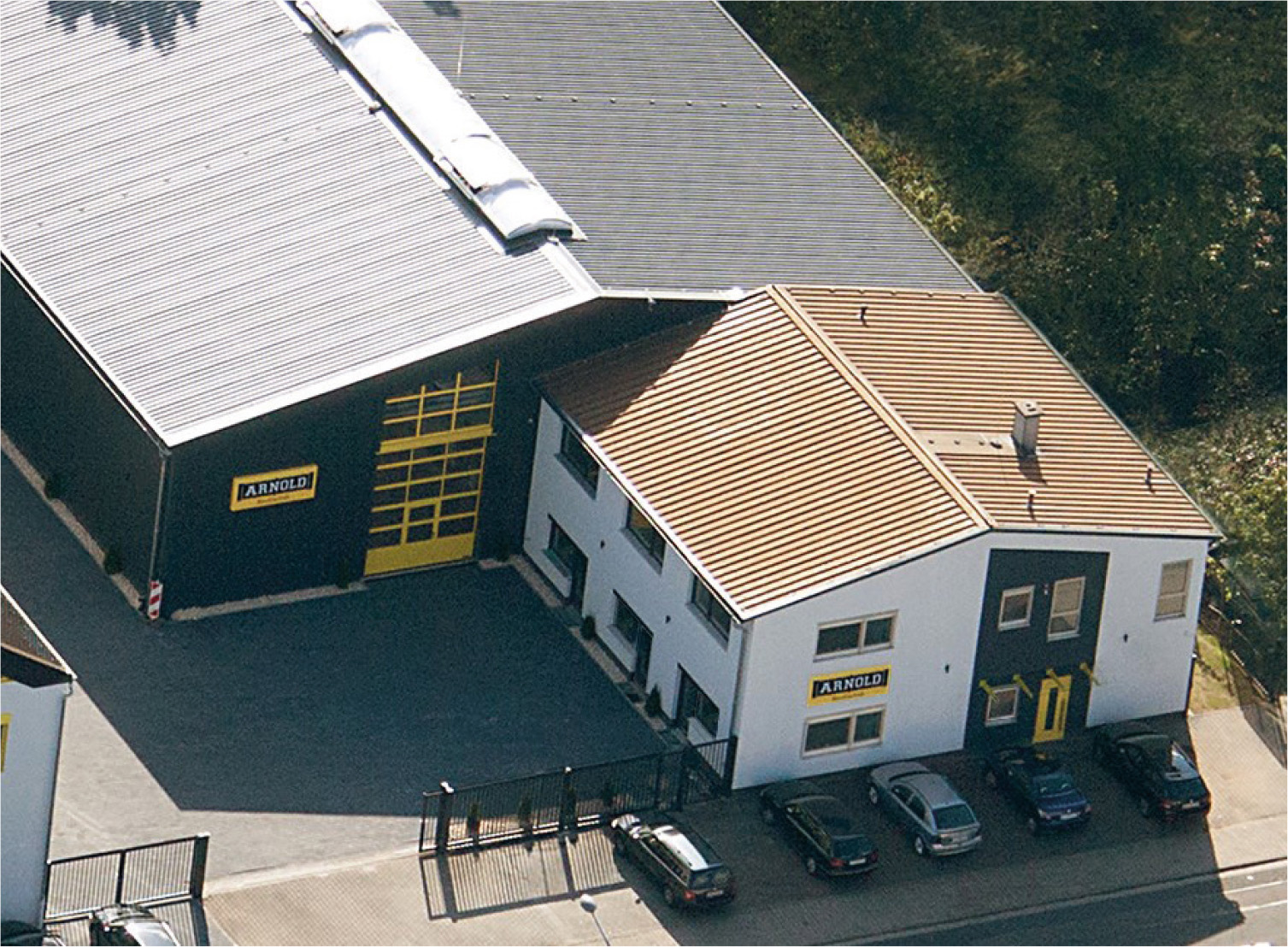

The rapid and positive development of the order situation in the field of protective cover systems as well as the expansion of product lines and new patent applications prompted Arno Arnold to build a new production and administration building.

A suitable site was found in the vicinity of the previous production facility and in 1989 it was possible to increase production in the new premises in accordance with new state-of-the-art work processes.

-

1984

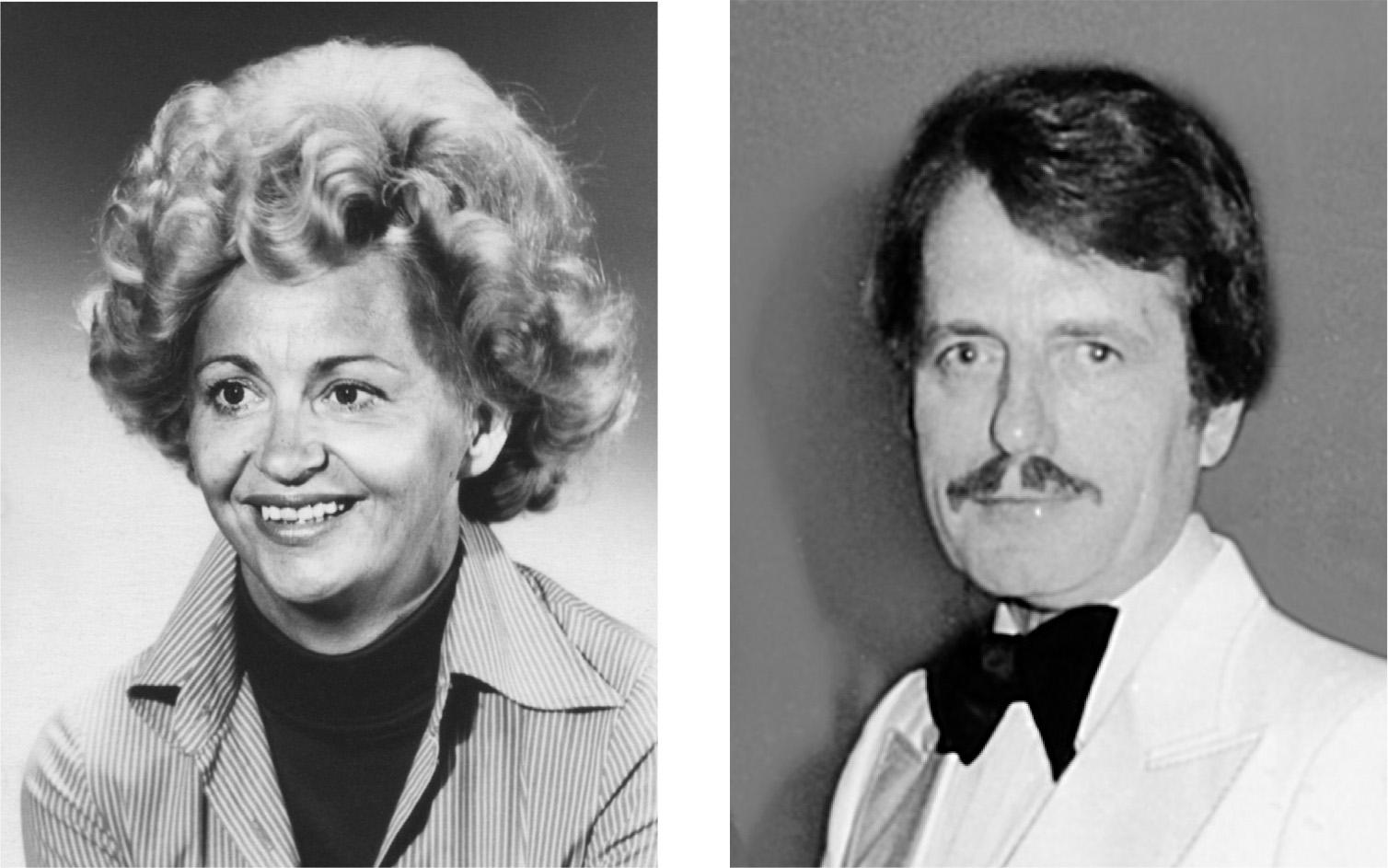

When Arno Arnold's granddaughter Simone Weinmann-Mang and her husband Wolf Matthias Mang took over the management of the company, the companies Weinmann Faltenbälge and Arno Arnold merged in the eighties to form ARNO ARNOLD GMBH as an international contact in the field of protection and safety systems.

-

1971

In 1971, the company finally said goodbye to the bandoneon. But not from the traditional commitment to manufacture high quality products that meet customer requirements.

-

1955

The gradual but decisive step from music to machines was made when Günter Weinmann and his wife Sigrid Weinmann, née Arnold, joined the company. He founded Weinmann-Faltenbälge GmbH, which developed the original WMB spiral, a conical spring spiral for protecting spindles as well as shafts, and was granted a patent for the manufacturing process in many European countries. The production of slideway protectors and camera bellows also became more and more the focus of the company.

-

1953

The company moved into its first own premises and already had a considerable number of qualified employees.

Whether it was because of the skilled workers of the leather goods manufacturers, the raw material leather itself, or friendly relations, is not flawlessly vouched for. In any case, it was not land or investment grants financed by the municipality. There was no such thing at that time - only entrepreneurial risk. And that was rewarded.

The bandoneon still played an important role in the "new" Arno Arnold company. But the change was unstoppable. The company kept pace with the reconstruction of the German economy and concentrated more and more on the production of bellows.

-

1949

1949 - the Federal Republic came into being and Arno Arnold found new entrepreneurial courage in Obertshausen, Hessen.

The first serial production of bandoneons could be manufactured by hand under the direction of Arno Arnold after the reconstruction in West Germany.

-

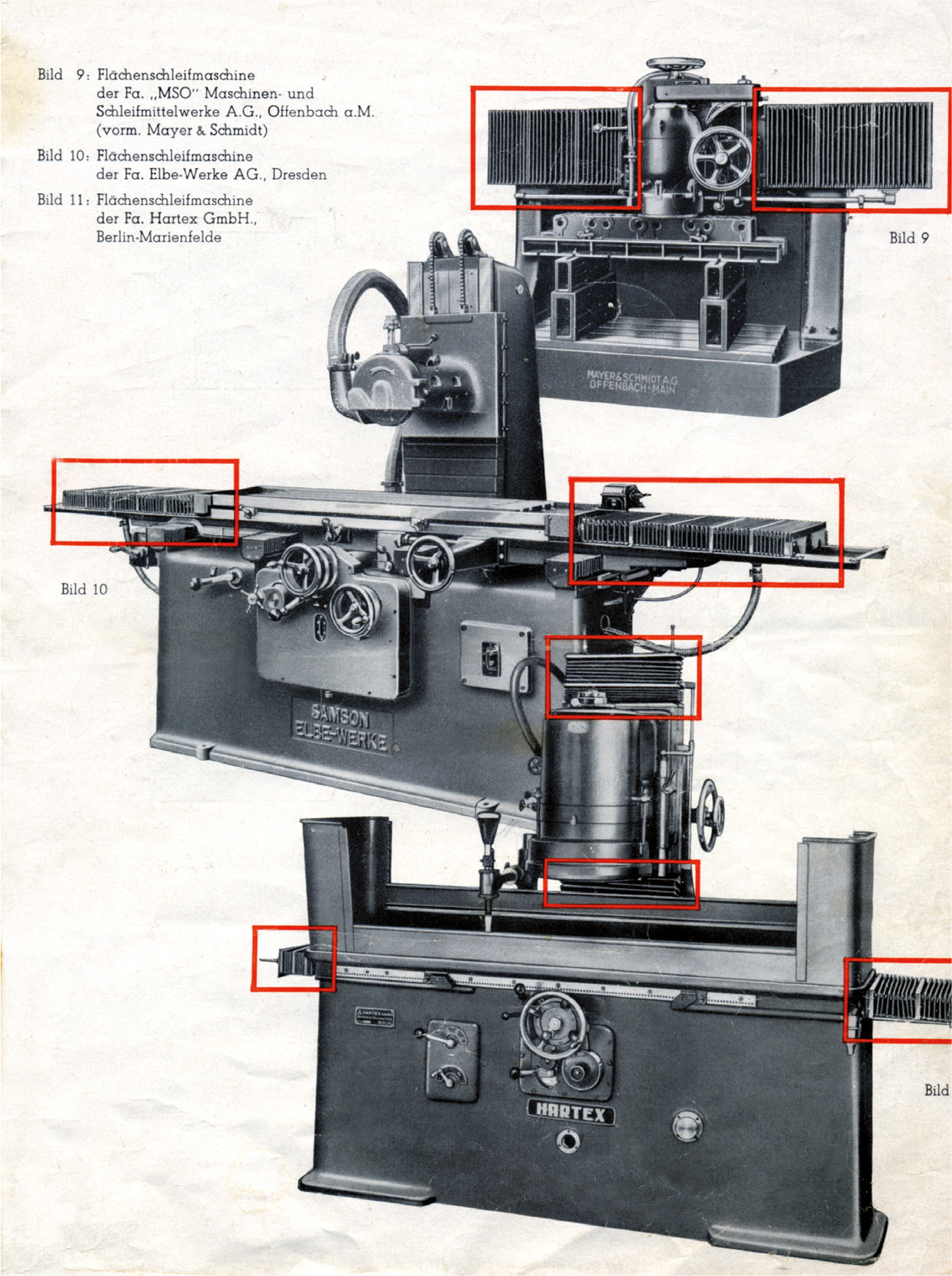

1930

In 1930, the Reich Patent Office granted the company Arnold in Carlsfeld a patent for a "harmonica-shaped bellows for the protective cover of guideways on machine tools, in particular on slide guides for grinding machines". If you look at the associated design drawings in layman's terms, you can almost see the bandoneon technique in front of you.

The bellows developed as a second mainstay alongside the world-famous "AA" bandoneons. And there were also advances in bandoneon manufacturing. In order to speed up the work processes, Arnold wrote in 1942 on the subject of "What tools do I need for the first operations": A 3-spindle drill to prevent changing drills while working.

-

1910

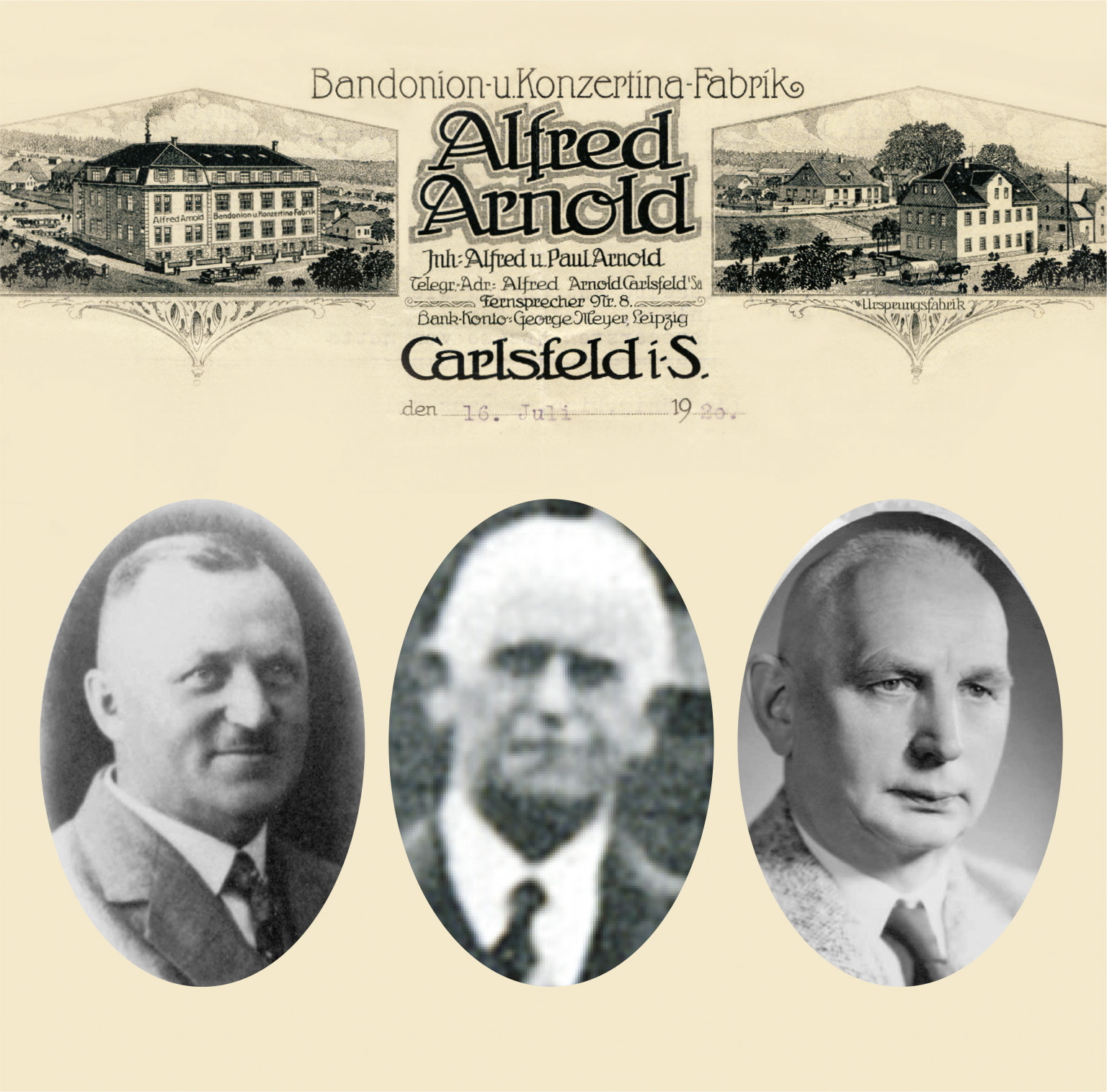

After ELA ended, the son of Ernst Louis Arnold, Alfred Arnold founded the Alfred Arnold company in 1910. His brother Wilhelm Paul Arnold joined the company in 1911 and involved his son Arno Arnold. He became a member of the management in 1930. From 1933 Arno Arnold managed the company as sole managing director.

-

1890

The bandoneon manufacturing company grew with the popularity of the musical instrument. The bellows instrument enjoyed growing popularity in the "bandonion clubs" of the labor movement, especially in the Ruhr and Saxony.

Arnold's beginnings are inextricably linked with the tango. This fashionable dance, which originated in Argentina, conquered the bars and brothels of big cities all over the world at the end of the 18th century. An instrument that interpreted the music of the tango like no other was the bandoneon, the flexible hand-pulled instrument whose bellows transported the air for the notes.

-

1864

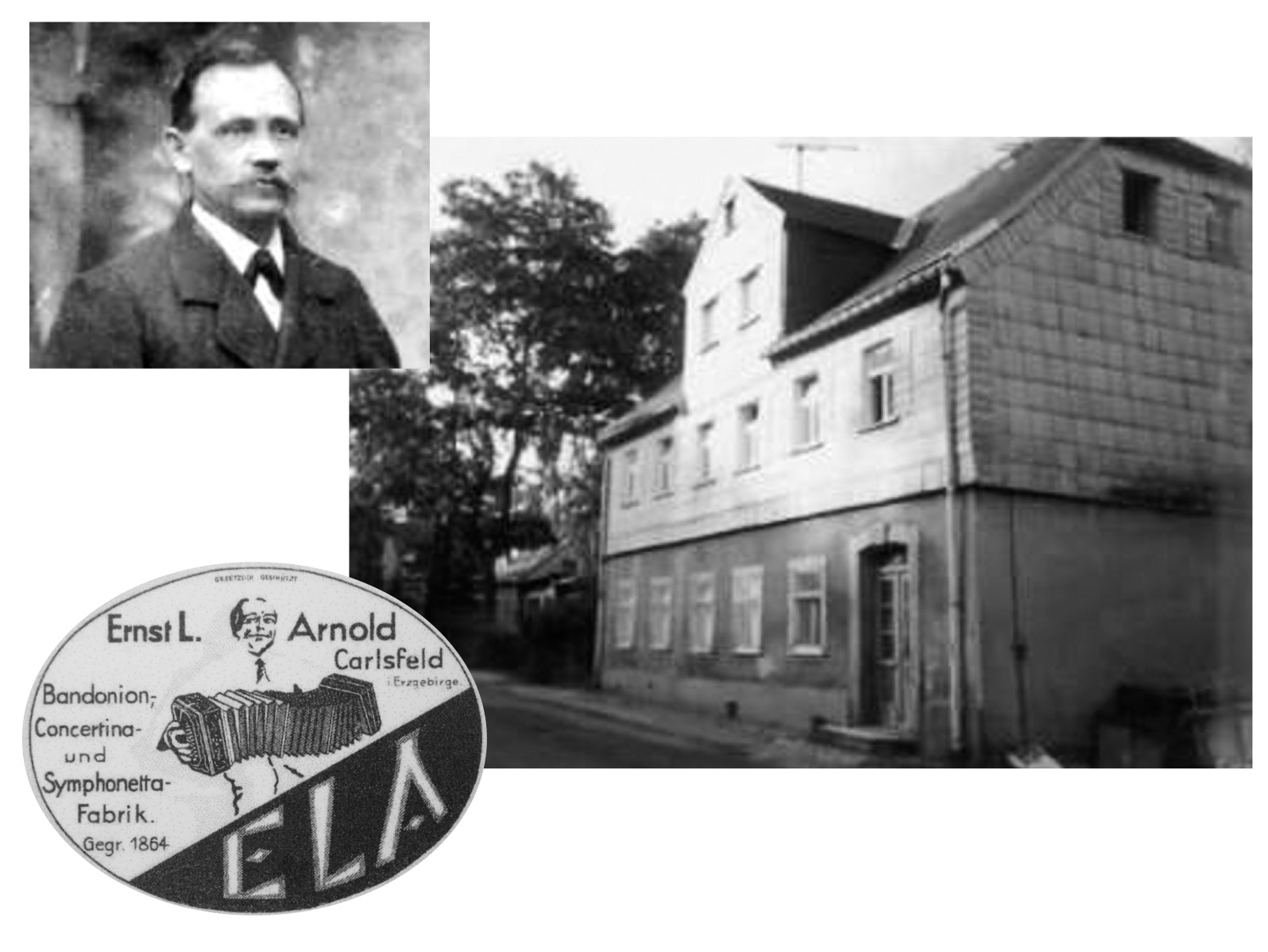

The foundation stone of the Arnold company dynasty was laid by Ernst Louis Arnold. He bought the invention of the "Carlsfeld concertina" from Carl Zimmermann before the latter emigrated to America in 1864.

His sons Ernst Alfred Arnold, Ernst Hermann Arnold and Wilhelm Paul Arnold also joined the company ELA, named after the first letters of Ernst Louis Arnold.

ARNO ARNOLD GmbH

Bieberer Straße 161

63179 Obertshausen

Germany

-

+49 (0)6104 4000-99

-

This email address is being protected from spambots. You need JavaScript enabled to view it.

MANAGEMENT

Isabelle Himbert,

Dr. Benedikt Himbert,

Wolf Mang

Reg.-Ger. Offenbach/M

5 B HRB 2567

USt-IdNr.: DE113530620